美国尼科NICO进口不锈钢化工泵为单级单吸悬臂式离心泵,其标记、额定性能点和尺寸等效采用国际标准ISO2858-1975(E)、美国尼科NICO进口不锈钢化工泵具有性能范围广、效率高、"三化"水平高和维修方便等特点,其效率比F型泵平均提高5%,是机械工业部确定取代F型耐腐蚀离心泵的节能、更新换代产品。供输送不含固体颗粒具有腐蚀性、粘度类似水的液体。

公称通径:25-300(mm)

流量范围:8-2600(m3/h)

扬程范围:7-150(m)

功率范围:1.5~18.5KW

转速范围:2900r/min

额定电压:DC24v、220v、380v,660v,1140v(DC、AC)

温度范围:-20℃~120℃

工作压力:≤1.6Mpa

泵体材质:铸铁、WCB、304、316、316L

进口不锈钢化工泵输送介质温度为-20℃~105℃,需要时采用双端面密封冷却装置,可输送介质温度为20℃~+280℃。适用于化工、石油、冶金、电力、造纸、食品、制药、环保、废水处理和合成纤维等行业用于输送各种腐蚀的或不允许污染的类似于水的介质。

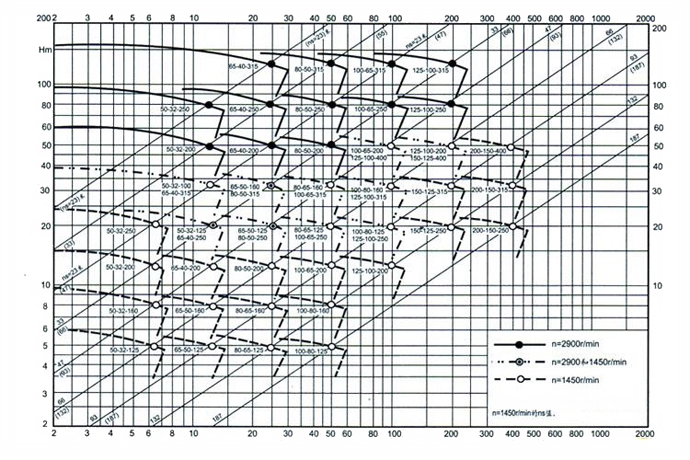

进口不锈钢化工泵的性能范围:进口不锈钢化工泵有29个基本型,其中22个双速(2900、1450r/min)经过A、B两种型式的叶轮直径切割变型后,达112个规格。

| 型号 | 转速 n | 流量 Q | 扬程 H | 效率 η | 功率 P | 必需汽蚀余量 | ||

| (r/min) | (m3/h) | (L/S) | (m) | (%) | 轴功率 | 电机功率 | (NPSH)r | |

| (KW) | (m) | |||||||

| BXNK50-32-125 | 2900 | 12.5 | 3.47 | 20 | 51 | 1.33 | 2.2 | 2 |

| 1450 | 6.3 | 1.75 | 5 | 45 | 0.19 | 0.55 | 2 | |

| BXNK50-32-125A | 2900 | 11.3 | 3.14 | 16.4 | 50 | 1.01 | 1.5 | 2 |

| 1450 | 5.7 | 1.58 | 4.1 | 43 | 0.15 | 0.55 | 2 | |

| BXNK50-32-160 | 2900 | 12.5 | 3.47 | 32 | 46 | 2.37 | 3 | 2 |

| 1450 | 6.3 | 1.75 | 8 | 40 | 0.34 | 0.55 | 2 | |

| BXNK50-32-160A | 2900 | 11.3 | 3.14 | 26.4 | 44 | 1.85 | 3 | 2 |

| 1450 | 5.7 | 1.58 | 6.6 | 37.1 | 0.28 | 0.55 | 2 | |

| BXNK50-32-200 | 2900 | 12.5 | 3.47 | 50 | 39 | 4.36 | 5.5 | 2 |

| 1450 | 6.3 | 1.75 | 12.5 | 33 | 0.65 | 1.1 | 2 | |

| BXNK50-32-200A | 2900 | 11.3 | 3.14 | 41 | 38 | 3.24 | 4 | 2 |

| 1450 | 5.7 | 1.58 | 10.3 | 31 | 0.52 | 0.75 | 2 | |

| BXNK50-32-250 | 2900 | 12.5 | 3.47 | 80 | 33 | 8.25 | 11 | 2 |

| 1450 | 6.3 | 1.75 | 20 | 27 | 1.27 | 2.2 | 2 | |

| BXNK50-32-250A | 2900 | 11.7 | 3.25 | 70 | 32 | 6.97 | 11 | 2 |

| 1450 | 5.9 | 1.64 | 17.5 | 25 | 1.25 | 1.5 | 2 | |

| BXNK50-32-250B | 2900 | 11 | 3.06 | 62 | 30 | 6.19 | 7.5 | 2 |

| BXNK65-50-125 | 2900 | 25 | 6.94 | 20 | 62 | 2.2 | 3 | 2 |

| 1450 | 12.5 | 3.47 | 5 | 55 | 0.31 | 0.55 | 2 | |

| BXNK65-50-125A | 2900 | 22.7 | 6.31 | 16.5 | 61 | 1.67 | 2.2 | 2 |

| 1450 | 11.3 | 3.14 | 4.1 | 54 | 0.23 | 0.55 | 2 | |

| BXNK65-50-160 | 2900 | 25 | 6.94 | 32 | 57 | 3.82 | 5.5 | 2 |

| 1450 | 12.5 | 3.47 | 8 | 51 | 0.53 | 0.75 | 2 | |

| BXNK65-50-160A | 2900 | 22.7 | 6.31 | 26.5 | 56 | 2.93 | 4 | 2 |

| 1450 | 11.3 | 3.14 | 6.6 | 49.6 | 0.41 | 0.55 | 2 | |

| BXNK65-40-200 | 2900 | 25 | 6.94 | 50 | 52 | 6.55 | 11 | 2 |

| 1450 | 12.5 | 3.47 | 12.5 | 46 | 0.93 | 1.5 | 2 | |

| BXNK65-40-200A | 2900 | 22.7 | 6.31 | 41 | 50 | 5.07 | 7.5 | 2 |

| 1450 | 11.3 | 3.14 | 10.3 | 44 | 0.72 | 1.1 | 2 | |

| BXNK65-40-250 | 2900 | 25 | 6.94 | 80 | 46 | 11.84 | 15 | 2 |

| 1450 | 12.5 | 3.47 | 20 | 39 | 1.75 | 3 | 2 | |

| BXNK65-40-250A | 2900 | 23.4 | 6.5 | 74.8 | 45 | 10.6 | 15 | 2 |

| 1450 | 11.7 | 3.25 | 17.5 | 37.9 | 1.47 | 2.2 | 2 | |

| BXNK65-40-250B | 2900 | 22 | 6.11 | 61.8 | 44 | 8.42 | 11 | 2 |

| BXNK65-40-315 | 2900 | 25 | 6.94 | 125 | 39 | 21.8 | 30 | 2 |

| 1450 | 12.5 | 3.47 | 32 | 33 | 3.3 | 5.5 | 2 | |

| BXNK65-40-315A | 2900 | 23.4 | 6.5 | 109.5 | 38 | 18.36 | 30 | 2 |

| 1450 | 11.7 | 3.25 | 28 | 33 | 2.71 | 4 | 2 | |

| BXNK65-40-315B | 2900 | 22 | 6.11 | 96.5 | 37 | 15.63 | 22 | 2 |

| BXNK80-65-125 | 2900 | 50 | 13.89 | 20 | 69 | 3.95 | 5.5 | 3 |

| 1450 | 25 | 6.94 | 5 | 64 | 0.53 | 0.75 | 2.5 | |

| BXNK80-65-125A | 2900 | 45.3 | 12.58 | 16.5 | 67 | 3.04 | 4 | 3 |

| 1450 | 22.7 | 6.31 | 4.1 | 62 | 0.41 | 0.55 | 2.5 | |

| BXNK80-65-160 | 2900 | 50 | 13.89 | 32 | 67 | 6.51 | 11 | 2.3 |

| 1450 | 25 | 6.94 | 8 | 62 | 0.88 | 1.5 | 2.3 | |

| BXNK80-65-160A | 2900 | 45.3 | 12.58 | 26.4 | 65 | 5.02 | 7.5 | 2.3 |

| 1450 | 22.7 | 6.31 | 6.6 | 60 | 0.68 | 1.1 | 2.3 | |

| BXNK80-50-200 | 2900 | 50 | 13.89 | 50 | 63 | 10.81 | 15 | 2.5 |

| 1450 | 25 | 6.94 | 12.5 | 57 | 1.49 | 2.2 | 2 | |

| BXNK80-50-200A | 2900 | 45.3 | 12.58 | 41 | 61 | 8.29 | 11 | 2.5 |

| 1450 | 22.7 | 6.31 | 10.3 | 56.1 | 1.14 | 2.2 | 2 | |

| BXNK80-50-250 | 2900 | 50 | 13.89 | 80 | 53 | 20.57 | 30 | 2.5 |

| 1450 | 25 | 6.94 | 20 | 50 | 2.72 | 5.5 | 2 | |

| BXNK80-50-250A | 2900 | 45.3 | 12.58 | 65.7 | 52 | 15.61 | 22 | 2.5 |

| 1450 | 22.7 | 6.31 | 16.4 | 49 | 2.07 | 3 | 2 | |

| BXNK80-50-315 | 2900 | 50 | 13.89 | 125 | 50 | 34.1 | 45 | 2.5 |

| 1450 | 25 | 6.94 | 32 | 48 | 4.54 | 7.5 | 2.5 | |

| BXNK80-50-315A | 2900 | 45.3 | 12.58 | 102.6 | 48 | 26.4 | 37 | 2.5 |

| 1450 | 22.7 | 6.31 | 25.7 | 46 | 3.46 | 5.5 | 2.5 | |

| BXNK100-80-125 | 2900 | 100 | 27.78 | 20 | 73 | 7.47 | 11 | 4.2 |

| 1450 | 50 | 13.89 | 5 | 69 | 0.99 | 1.5 | 3.4 | |

| BXNK100-80-125A | 2900 | 91.8 | 25.5 | 16.8 | 71 | 5.92 | 7.5 | 4.2 |

| 1450 | 45.9 | 12.75 | 4.2 | 67 | 0.78 | 1.1 | 3.4 | |

| BXNK100-80-160 | 2900 | 100 | 27.78 | 32 | 73 | 11.9 | 15 | 4.3 |

| 1450 | 50 | 13.89 | 8 | 68 | 1.58 | 2.2 | 3.4 | |

| BXNK100-80-160A | 2900 | 91 | 25.28 | 26.5 | 71 | 9.25 | 15 | 4.3 |

| 1450 | 45.5 | 12.64 | 6.6 | 67 | 1.22 | 1.5 | 3.4 | |

| BXNK100-65-200 | 2900 | 100 | 27.78 | 50 | 72 | 18.92 | 22 | 3.9 |

| 1450 | 50 | 13.89 | 12.5 | 68 | 2.5 | 3 | 2.5 | |

| BXNK100-65-200A | 2900 | 91 | 25.28 | 41.5 | 70 | 14.7 | 18.5 | 3.9 |

| 1450 | 45.5 | 12.64 | 10.3 | 66 | 1.93 | 3 | 2.5 | |

| BXNK100-65-250 | 2900 | 100 | 27.78 | 80 | 68 | 32.06 | 37 | 3.6 |

| 1450 | 50 | 13.89 | 20 | 63 | 4.33 | 5.5 | 2.5 | |

| BXNK100-65-250A | 2900 | 93.5 | 25.97 | 70 | 65 | 27.44 | 37 | 3.6 |

| 1450 | 45.5 | 12.64 | 17.4 | 61 | 3.53 | 5.5 | 2.5 | |

| BXNK100-65-250B | 2900 | 87.8 | 24.39 | 61.7 | 64 | 23.1 | 30 | 3.6 |

| BXNK100-65-315 | 2900 | 100 | 27.78 | 125 | 62 | 54.94 | 75 | 3.2 |

| 1450 | 50 | 13.89 | 32 | 58 | 7.52 | 11 | 2 | |

| BXNK100-65-315A | 2900 | 93.5 | 25.97 | 109 | 61 | 45.53 | 75 | 3.2 |

| 1450 | 46.5 | 12.92 | 28 | 56 | 6.33 | 11 | 2 | |

| BXNK100-65-315B | 2900 | 88 | 24.44 | 97 | 60 | 38.77 | 55 | 3.2 |

| BXNK125-100-200 | 2900 | 200 | 55.56 | 50 | 77 | 35.39 | 45 | 5 |

| 1450 | 100 | 27.78 | 12.5 | 73 | 4.66 | 7.5 | 2.9 | |

| BXNK125-100-200A | 2900 | 182 | 50.56 | 41.4 | 75 | 27.38 | 37 | 5 |

| 1450 | 91 | 25.28 | 10.3 | 71 | 3.6 | 5.5 | 2.9 | |

| BXNK125-100-250 | 2900 | 200 | 55.56 | 80 | 75 | 58.13 | 75 | 4.5 |

| 1450 | 100 | 27.78 | 20 | 72 | 7.56 | 11 | 2.3 | |

| BXNK125-100-250A | 2900 | 186.5 | 51.81 | 69.5 | 73 | 48.35 | 75 | 4.5 |

| 1450 | 93 | 25.83 | 17.4 | 70 | 6.29 | 11 | 2.3 | |

| BXNK125-100-250B | 2900 | 175.5 | 48.75 | 61.5 | 71 | 41.42 | 55 | 4.5 |

| BXNK125-100-315 | 2900 | 200 | 55.6 | 125 | 72 | 94.62 | 110 | 4.5 |

| 1450 | 100 | 27.8 | 32 | 65 | 13.42 | 22 | 2.5 | |

| BXNK125-100-315A | 2900 | 186.5 | 51.81 | 108.7 | 71 | 77.81 | 90 | 4.5 |

| 1450 | 93 | 25.83 | 27.2 | 64 | 10.77 | 15 | 2.5 | |

| BXNK125-10-400 | 1450 | 100 | 27.78 | 50 | 55 | 24.77 | 30 | 2.5 |

| BXNK125-100-400A | 1450 | 93 | 25.83 | 43.2 | 54 | 20.27 | 30 | 2.5 |

| BXNK150-125-250 | 1450 | 200 | 55.56 | 20 | 77 | 14.16 | 18.5 | 2.8 |

| BXNK150-125-250A | 1450 | 182 | 50.56 | 16.5 | 75 | 10.91 | 15 | 2.8 |

| BXNK150-125-315 | 1450 | 200 | 55.6 | 32 | 75 | 23.25 | 30 | 2.8 |

| BXNK150-125-315A | 1450 | 182 | 50.56 | 25.5 | 73 | 17.32 | 22 | 2.8 |

| BXNK150-125-315B | 1450 | 165 | 45.83 | 22 | 72 | 13.74 | 18.5 | 2.8 |

| BXNK150-125-400 | 1450 | 200 | 55.56 | 50 | 70 | 38.93 | 55 | 2.5 |

| BXNK150-125-400A | 1450 | 182 | 50.56 | 41 | 68 | 29.94 | 37 | 2.5 |

| BXNK150-125-400B | 1450 | 165 | 45.83 | 34 | 67 | 22.82 | 30 | 2.5 |

| BXNK200-150-250 | 1450 | 400 | 111.11 | 20 | 79 | 27.59 | 37 | 2.8 |

| BXNK200-150-250A | 1450 | 363 | 100.83 | 16.5 | 79 | 20.66 | 30 | 2.8 |

| BXNK200-150-315 | 1450 | 400 | 111.11 | 32 | 79 | 44.15 | 55 | 3.5 |

| BXNK200-150-315A | 1450 | 363 | 100.84 | 25.5 | 77 | 32.76 | 45 | 3.5 |

| BXNK200-150-315B | 1450 | 329 | 91.39 | 21.6 | 76 | 25.48 | 37 | 3.5 |

| BXNK200-150-400 | 1450 | 400 | 111.11 | 50 | 78 | 69.87 | 90 | 3.5 |

| BXNK200-150-400A | 1450 | 363 | 100.83 | 41 | 76 | 53.36 | 75 | 3.5 |

| BXNK200-150-400B | 1450 | 329 | 91.39 | 33.8 | 75 | 40.4 | 55 | 3.5 |

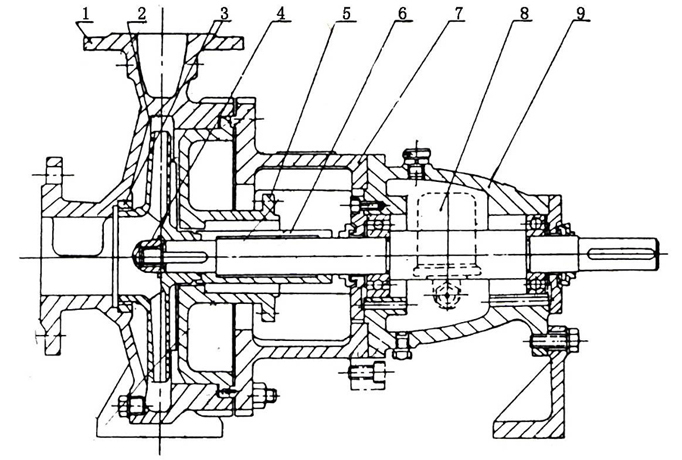

| 1 | 泵体 | 2 | 叶轮 | 3 | 密封环 | 4 | 叶轮螺母 | 5 | 泵盖 |

| 6 | 密封部件 | 7 | 中间支架 | 8 | 轴 | 9 | 悬架部件 | ||

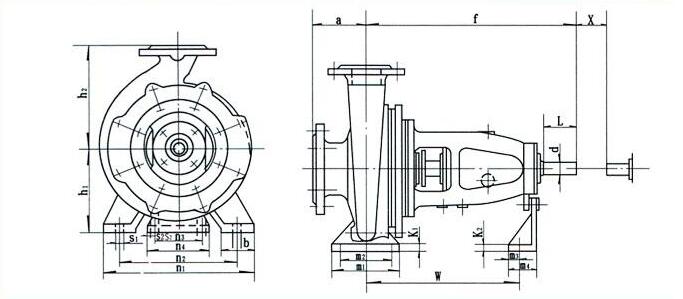

| 序 号 | 泵型号 | 泵外形尺寸 | 泵底板及安装尺寸 | ||||||||||||||||

| a | f | h1 | h2 | b | p1 | p2 | ml | m2 | nl | n2 | n3 | n4 | tl | t2 | w | s1 | s2 | ||

| 1 | 50-32-160 | 80 | 385 | 132 | 160 | 50 | 118 | 128 | 100 | 70 | 240 | 190 | 110 | 160 | 12 | 6 | 285 | 14 | 14 |

| 2 | 50-32-200 | 80 | 385 | 160 | 180 | 50 | 139 | 147 | 100 | 70 | 240 | 190 | 110 | 160 | 12 | 6 | 285 | 14 | 14 |

| 3 | 65-50-160 | 80 | 385 | 132 | 160 | 50 | 121 | 136 | 100 | 70 | 240 | 190 | 110 | 160 | 12 | 6 | 285 | 14 | 14 |

| 4 | 65-40-200 | 100 | 385 | 160 | 180 | 50 | 140 | 151 | 100 | 70 | 265 | 212 | 110 | 160 | 13 | 6 | 285 | 14 | 14 |

| 5 | 65-40-250 | 100 | 500 | 180 | 225 | 65 | 166 | 176 | 125 | 95 | 320 | 250 | 110 | 160 | 14 | 6 | 370 | 14 | 14 |

| 6 | 65-40-315 | 125 | 500 | 200 | 250 | 65 | 194 | 200 | 125 | 95 | 345 | 280 | 110 | 160 | 16 | 6 | 370 | 14 | 14 |

| 7 | 80-65-160 | 100 | 385 | 160 | 180 | 50 | 124 | 143 | 100 | 70 | 265 | 212 | 110 | 160 | 13 | 6 | 285 | 14 | 14 |

| 8 | 80-50-200 | 100 | 385 | 160 | 200 | 52 | 147 | 161 | 100 | 70 | 265 | 212 | 110 | 160 | 13 | 6 | 285 | 14 | 14 |

| 9 | 80-50-250 | 125 | 500 | 180 | 225 | 65 | 167 | 179 | 125 | 95 | 320 | 250 | 110 | 160 | 15 | 6 | 370 | 14 | 14 |

| 10 | 80-50-315 | 125 | 500 | 225 | 280 | 65 | 204 | 215 | 125 | 95 | 345 | 280 | 110 | 160 | 18 | 6 | 370 | 14 | 14 |

| 11 | 100-65-200 | 100 | 500 | 180 | 225 | 65 | 159 | 183 | 125 | 95 | 320 | 250 | 110 | 160 | 14 | 6 | 370 | 14 | 14 |

| 12 | 100-65-250 | 125 | 500 | 200 | 250 | 80 | 180 | 201 | 160 | 120 | 360 | 280 | 110 | 160 | 16 | 6 | 370 | 18 | 14 |

| 13 | 100-65-315 | 125 | 530 | 225 | 280 | 80 | 210 | 228 | 160 | 120 | 400 | 315 | 110 | 160 | 18 | 6 | 370 | 18 | 14 |

| 14 | 100-80-160 | 100 | 500 | 160 | 200 | 65 | 132 | 160 | 125 | 95 | 280 | 212 | 110 | 160 | 14 | 6 | 370 | 14 | 14 |

| 15 | 125-80-400 | 125 | 530 | 280 | 355 | 80 | 261 | 279 | 160 | 120 | 435 | 355 | 110 | 160 | 20 | 6 | 370 | 18 | 14 |

| 16 | 125-100-200 | 125 | 500 | 200 | 280 | 80 | 175 | 210 | 160 | 120 | 360 | 280 | 110 | 160 | 17 | 6 | 370 | 18 | 14 |

| 17 | 125-100-250 | 140 | 530 | 225 | 280 | 80 | 193 | 225 | 160 | 120 | 400 | 315 | 110 | 160 | 18 | 6 | 370 | 18 | 14 |

| 18 | 125-100-315 | 140 | 530 | 250 | 315 | 80 | 224 | 250 | 160 | 120 | 400 | 315 | 110 | 160 | 19 | 6 | 370 | 18 | 14 |

| 19 | 125-100-400 | 140 | 530 | 280 | 355 | 100 | 265 | 287 | 200 | 150 | 500 | 400 | 110 | 160 | 20 | 6 | 370 | 18 | 14 |

| 20 | 150-125-250 | 140 | 530 | 250 | 355 | 80 | 204 | 244 | 160 | 120 | 400 | 315 | 110 | 160 | 19 | 6 | 370 | 18 | 14 |

| 21 | 150-125-315 | 140 | 530 | 280 | 355 | 100 | 236 | 271 | 200 | 150 | 500 | 400 | 110 | 160 | 20 | 6 | 370 | 22 | 14 |

| 22 | 150-125-400 | 140 | 530 | 315 | 400 | 100 | 273 | 301 | 200 | 150 | 500 | 400 | 110 | 160 | 21 | 6 | 370 | 22 | 14 |

| 23 | 200-150-315 | 160 | 670 | 315 | 400 | 82 | 255 | 304 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 24 | 200-150-400 | 160 | 670 | 315 | 450 | 82 | 291 | 330 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 25 | 250-200-315 | 180 | 670 | 315 | 450 | 82 | 278 | 344 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 26 | 250-200-400 | 180 | 670 | 380 | 450 | 82 | 314 | 367 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 序 号 | 泵型号 | 进水法兰尺寸 | 出水法兰尺寸 | 轴伸端尺寸 | 重量 (kg) | |||||||||||

| D1 | D2 | D3 | kl | dl | D4 | D5 | D6 | k2 | d2 | D | L | E | G | |||

| 1 | 50-32-160 | 50 | 125 | 165 | 4 | 18 | 32 | 100 | 140 | 4 | 18 | 24 | 50 | 8 | 20 | 40 |

| 2 | 50-32-200 | 50 | 125 | 165 | 4 | 18 | 32 | 100 | 140 | 4 | 18 | 24 | 50 | 8 | 20 | 48 |

| 3 | 65-50-160 | 65 | 145 | 185 | 4 | 18 | 50 | 125 | 165 | 4 | 18 | 24 | 50 | 8 | 20 | 42 |

| 4 | 65-40-200 | 65 | 145 | 185 | 4 | 18 | 40 | 110 | 150 | 4 | 18 | 24 | 50 | 8 | 20 | 50 |

| 5 | 65-40-250 | 65 | 145 | 185 | 4 | 18 | 40 | 110 | 150 | 4 | 18 | 32 | 80 | 10 | 27 | 72 |

| 6 | 65-40-315 | 65 | 145 | 185 | 4 | 18 | 40 | 110 | 150 | 4 | 18 | 32 | 80 | 10 | 27 | 82 |

| 7 | 80-65-160 | 80 | 160 | 200 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 24 | 50 | 8 | 20 | 48 |

| 8 | 80-50-200 | 80 | 160 | 200 | 8 | 18 | 50 | 125 | 165 | 4 | 18 | 24 | 50 | 8 | 20 | 54 |

| 9 | 80-50-250 | 80 | 160 | 200 | 8 | 18 | 50 | 125 | 165 | 4 | 18 | 32 | 80 | 10 | 27 | 75 |

| 10 | 80-50-315 | 80 | 160 | 200 | 8 | 18 | 50 | 125 | 165 | 4 | 18 | 32 | 80 | 10 | 27 | 90 |

| 11 | 100-65-200 | 100 | 180 | 220 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 32 | 80 | 10 | 27 | 73 |

| 12 | 100-65-250 | 100 | 180 | 220 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 32 | 80 | 10 | 27 | 82 |

| 13 | 100-65-315 | 100 | 180 | 220 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 42 | 110 | 12 | 37 | 120 |

| 14 | 100-80-160 | 100 | 180 | 220 | 8 | 18 | 80 | 160 | 200 | 8 | 18 | 32 | 80 | 10 | 27 | 70 |

| 15 | 125-80-400 | 125 | 210 | 250 | 8 | 18 | 80 | 160 | 200 | 8 | 18 | 42 | 110 | 12 | 37 | 168 |

| 16 | 125-100-200 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 32 | 80 | 10 | 27 | 88 |

| 17 | 125-100-250 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 42 | 110 | 12 | 37 | 130 |

| 18 | 125-100-315 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 42 | 110 | 12 | 37 | 138 |

| 19 | 125-100-400 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 42 | 110 | 12 | 37 | 178 |

| 20 | 150-125-250 | 150 | 240 | 285 | 8 | 22 | 125 | 210 | 250 | 8 | 18 | 42 | 106 | 12 | 37 | 134 |

| 21 | 150-125-315 | 150 | 240 | 285 | 8 | 22 | 125 | 210 | 250 | 8 | 18 | 42 | 106 | 12 | 37 | 167 |

| 22 | 150-125-400 | 150 | 240 | 285 | 8 | 22 | 125 | 210 | 250 | 8 | 18 | 42 | 106 | 12 | 37 | 186 |

| 23 | 200-150-315 | 200 | 295 | 340 | 12 | 22 | 150 | 240 | 285 | 8 | 22 | 60 | 110 | 18 | 53 | 228 |

| 24 | 200-150-400 | 200 | 295 | 340 | 12 | 22 | 150 | 240 | 285 | 8 | 22 | 60 | 110 | 18 | 53 | 285 |

| 25 | 250-200-315 | 250 | 355 | 405 | 12 | 26 | 200 | 295 | 340 | 12 | 22 | 60 | 110 | 18 | 53 | 264 |

| 26 | 250-200-400 | 250 | 355 | 405 | 12 | 26 | 200 | 295 | 340 | 12 | 22 | 60 | 110 | 18 | 53 | 335 |

1、泵的安装是否合理,对泵的正常运行和使用寿命有很重要的影响,所以安装前必须仔细校正,不得草率,泵的外形及安装尺寸,详见困5和表4。

2、必须保证泵在工作时不超过其允许汽蚀余量。泵的吸上高度《或倒灌高度)必须根据泵的汽蚀余量特性,管路阻力损失特性及高温水的吸入液面压力来确定。

泵吸上使用情况下,应在吸入管路上装上底阀,并在出口管路上设置壤液螺孔或阀门,以供起动前灌泵之用;

泵倒灌使用情况下,应在吸入管路上装上阀门和过滤器,以免杂物进入。

3、吸入和吐出管路应该另有支架,不能用泵作支承。

4、安装泵的地点,应便于巡回检查和检修。

5、安装顺序

① 将机组放在埋有地脚螺栓的基础上,在底座和基础之间放置成对的楔垫作找正之用。

② 松开联轴器。用水平仪分别放在泵轴或底座上,通过调整禊垫,找正机组的水平后,适当拧紧地脚螺栓,以防走动。

③ 用混凝土灌注底座和地脚螺检孔。

④ 待混凝土干涸后,应拧紧地脚螺栓,^并重新检查泵轴的氷平度。

⑤ 在接好管路及确定原动机转动方向以后,接上联轴器,再核对一遍轴的同心度,测量联轴器的外园上下,左右的差异不得超过0.1mm,两联轴器端面间隙,在一周内最大和最小的间咪差不得超过0.3mm.

⑥ 在机组实际运行3—4小时后作最后检查,如无不良现象,则认为安装合格。

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostruds exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered