美国尼科NICO进口管道离心泵产品可以简便安装于任一段水平管路中间。完全能满足高层建筑、深井矿等的给排水及消防设施需要,是广大行业冷热水或一般介质、理化性质类似水等液体输送的最佳泵型。管道泵吸入、排出口位于同一直线上。转子部件由轴、叶轮、叶轮挡套、轴套等零件组成,进水段、中段、出水段用拉紧螺栓联结。轴封采用机械密封,用平衡室的压力水进行润滑和冷却。是各大行业冷热水或物理化学性质类似于水等液体输送的最佳泵型。进口管道离心泵具有泵、机一体化结构紧凑,体积小、外形美观、运行平稳、安装方便、无噪音、零泄漏、无污染等特点,加之只有静止密封,能做到完全无泄露。电机自身低噪音,管道泵低故障率,高可靠性能,和维护成本低等优点。

公称通径:φ50-φ200

流量范围:4-300m3/h

扬程范围:13-650m

功率范围:2.2-400KW

转速范围:1450-2950r/min

温度范围 :-20+350℃

工作压力:≤6.0Mpa

泵体材质:WCB、304、316、四氟

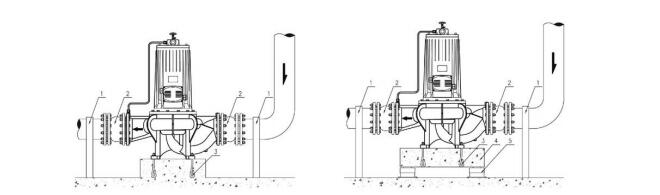

1、泵结构紧凑,机泵一体化,体积小。其立式结构具有安装占地面积小,运行平稳,安装无需调整。

2、泵进出口设计成规格相同法兰,且位于同一中心线上,可象阀门一样直接安装在管路上,且中心低,便于管道布置,安装特别方便。

3、泵与电机同轴,轴向尺寸短,使泵运行更加平稳,噪音低。

4、取消传统轴封方式,避免了输送介质的外泄,因此具有完全无泄露的显著特点。

5、用滑动轴承替代常规电机滚动轴承,使泵具有运行特别平稳,振动噪音极低。

6、安装检修方便,无需拆动管路系统,只要拆下连接体螺母即可抽出全部转子部件进行检查和维修。

7、可根据使用要求即流量和扬程的需要进行泵的串、并联运行方式。

1、进口管道离心泵普通型供输送清水及物理化学性质类似于清水的其他液体之用。介质使用温度不超过80℃,适用于工业和城市给排水,高层建筑增压送水、园林喷灌、消防增压、远距离输送、暖通制冷循环、浴室等冷暖水循环增压及设备配套。特别适用对振动、噪音要求较高的场合,如地下泵房、空调制冷系统等。

2、进口管道离心泵热水型主要供输送温度不超过160℃不含固体颗粒的软水之用,适用于能源、冶金、化工、纺织、造纸以及宾馆、饭店、浴室、锅炉热水增压循环输送及城市采暖系统循环等场合。

3、进口管道离心泵防腐型供输送不含固体颗粒,具有腐蚀性,粘度类似于水的液体,适用于石油、化工、冶金、电力、造纸、食品、制药和合成纤维等部门。

1、介质必须为软水、稀薄、不凝固、非易燃、不含固体颗粒及纤维的流体。

2、介质温度普通型80℃,热水型为120℃。

3、一般情况下系统工作压力不超过1.2Mpa,进口压力不小于0.5Mpa,特殊场合应事先与生产厂家联系。

4、环境温度不超过40℃,相对温度不超过95%。

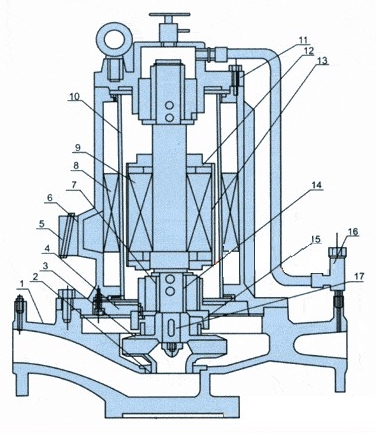

结构见图。进口管道离心泵为机泵一体结构,整机主要由泵体、叶轮、联接体、滑动轴承、定子、转子、屏蔽套、电机壳等零部件组成。泵为立式单级单吸离心式,进出口在同一水平轴线上,口径规格相同可直接象阀门一样安装在管路的任何部位上,装卸极为方便,占地面积省。泵通过联接体与电机或一体,轴承采用进口石墨浸渍树脂复合轴承,电子定转子各有屏蔽套进行隔离。轴承采用流体本身介质作为润滑剂及冷却液,具有设计合理、运行可靠的特点。泵设有底座,可直接安装在地基上,因该泵具有低噪音,无振动特点,安装时无需加装隔振器或隔振垫

| 1 | 泵体 | 7 | 自动排气阀 | 13 | 转子组件 | 19 | 下石墨轴承组件 |

| 2 | 叶轮 | 8 | 循环水管 | 14 | 定子屏蔽套 | 20 | 井帽 |

| 3 | 电机下端盖 | 9 | 上石墨轴承组件 | 15 | 转子屏蔽套 | 21 | 键 |

| 4 | 电机壳 | 10 | 上屏蔽压盘 | 16 | 接线盒 | 22 | 叶轮井帽 |

| 5 | 电机上端盖 | 11 | 上推力盘 | 17 | 下推力盘 | 23 | 过滤网 |

| 6 | 吊环 | 12 | 定子组件 | 18 | 下屏蔽压盘 |

| 序号 | 型号 | 流量 | 扬程(m) | 效率 | 转速 | 电机功率(kw) | 必须汽蚀余量 | |

| m³/h | L/S | |||||||

| 1 | GD40-100 | 6.3 | 1.75 | 12.5 | 54 | 1450 | 0.55 | 3.5 |

| 2 | GD40-100A | 5.6 | 1.56 | 10 | 52 | 1450 | 0.37 | 3.5 |

| 3 | GD40-125 | 6.3 | 1.75 | 20 | 46 | 1450 | 1.1 | 3.5 |

| 4 | GD40-125A | 5.6 | 1.56 | 16 | 45 | 2900 | 0.75 | 3.5 |

| 5 | GD40-160 | 6.3 | 1.75 | 32 | 40 | 2900 | 2.2 | 3.5 |

| 6 | GD40-160A | 5.9 | 1.64 | 28 | 39 | 2900 | 1.5 | 3.5 |

| 7 | GD40-160B | 5.5 | 1.53 | 24 | 38 | 2900 | 1.1 | 3.5 |

| 8 | GD40-200 | 6.3 | 1.75 | 50 | 33 | 2900 | 4 | 3.5 |

| 9 | GD40-200A | 5.9 | 1.64 | 44 | 31 | 2900 | 3 | 3.5 |

| 10 | GD40-200B | 5.3 | 1.47 | 36 | 29 | 2900 | 2.2 | 3.5 |

| 11 | GD40-250 | 6.3 | 1.75 | 80 | 28 | 2900 | 7.5 | 3.5 |

| 12 | GD40-250A | 5.9 | 1.64 | 70 | 28 | 2900 | 5.5 | 3.5 |

| 13 | GD40-250B | 5.5 | 1.53 | 60 | 27 | 2900 | 4 | 3.5 |

| 14 | GD40-100(I) | 12.5 | 3.47 | 12.5 | 62 | 1450 | 1.1 | 3.5 |

| 15 | GD40-100(I)A | 11 | 3.05 | 10 | 60 | 1450 | 0.75 | 3.5 |

| 16 | GD40-125(I) | 12.5 | 3.47 | 20 | 58 | 1450 | 1.5 | 3.5 |

| 17 | GD40-125(I)A | 11 | 3.05 | 16 | 57 | 1450 | 1.1 | 3.5 |

| 18 | GD40-160(I) | 12.5 | 3.47 | 32 | 52 | 2900 | 3 | 3.5 |

| 19 | GD40-160(I)A | 11.7 | 3.25 | 28 | 51 | 2900 | 2.2 | 3.5 |

| 20 | GD40-160(I)B | 10.4 | 2.89 | 22 | 50 | 2900 | 1.5 | 3.5 |

| 21 | GD40-200(I) | 12.5 | 3.47 | 50 | 46 | 2900 | 5.5 | 3.5 |

| 22 | GD40-200(I)A | 11.7 | 3.25 | 44 | 45 | 2900 | 4 | 3.5 |

| 23 | GD40-200(I)B | 10.6 | 2.94 | 36 | 44 | 2900 | 3 | 3.5 |

| 24 | GD40-250(I) | 12.5 | 3.47 | 80 | 38 | 2900 | 11 | 3.5 |

| 25 | GD40-250(I)A | 11.6 | 3.22 | 70 | 38 | 2900 | 7.5 | 3.5 |

| 26 | GD40-250(I)B | 10.8 | 3 | 60 | 37 | 2900 | 7.5 | 3.5 |

| 27 | GD40-250(I)C | 10 | 2.78 | 52 | 36 | 2900 | 5.5 | 3.5 |

| 28 | GD50-100 | 12.5 | 3.47 | 12.5 | 62 | 1450 | 1.1 | 3.5 |

| 29 | GD50-100A | 11 | 3.05 | 10 | 60 | 1450 | 0.75 | 3.5 |

| 30 | GD50-125 | 12.5 | 3.47 | 20 | 58 | 1450 | 1.5 | 3.5 |

| 31 | GD50-125A | 11 | 3.05 | 16 | 57 | 1450 | 1.1 | 3.5 |

| 32 | GD50-160 | 12.5 | 3.47 | 32 | 52 | 2900 | 3 | 3.5 |

| 33 | GD50-160A | 11.7 | 3.25 | 28 | 51 | 2900 | 2.2 | 3.5 |

| 34 | GD50-160B | 10.4 | 2.89 | 22 | 50 | 2900 | 1.5 | 3.5 |

| 35 | GD50-200 | 12.5 | 3.47 | 50 | 46 | 2900 | 5.5 | 3.5 |

| 36 | GD50-200A | 11.7 | 3.25 | 44 | 45 | 2900 | 4 | 3.5 |

| 37 | GD50-200B | 10.6 | 2.94 | 36 | 44 | 2900 | 3 | 3.5 |

| 38 | GD50-250 | 12.5 | 3.47 | 80 | 38 | 2900 | 11 | 3.5 |

| 39 | GD50-250A | 11.6 | 3.22 | 70 | 38 | 2900 | 7.5 | 3.5 |

| 40 | GD50-250B | 10.8 | 3 | 60 | 37 | 2900 | 7.5 | 3.5 |

| 41 | GD50-250C | 10 | 2.78 | 52 | 36 | 2900 | 5.5 | 3.5 |

| 42 | GD50-100(I) | 25 | 6.94 | 12.5 | 69 | 1450 | 1.5 | 3.8 |

| 43 | GD50-100(I)A | 22.3 | 6.19 | 10 | 67 | 1450 | 1.1 | 3.8 |

| 44 | GD50-125(I) | 25 | 6.94 | 20 | 68 | 1450 | 3 | 3.8 |

| 45 | GD50-125(I)A | 22.3 | 6.49 | 16 | 66 | 1450 | 2.2 | 3.8 |

| 46 | GD50-160(I) | 25 | 6.94 | 32 | 63 | 1450 | 4 | 3.8 |

| 47 | GD50-160(I)A | 23.4 | 6.5 | 28 | 62 | 1450 | 4 | 3.8 |

| 48 | GD50-160(I)B | 21.6 | 6 | 24 | 58 | 1450 | 3 | 3.8 |

| 49 | GD50-200(I) | 25 | 6.94 | 50 | 58 | 2900 | 7.5 | 3.8 |

| 50 | GD50-200(I)A | 23.5 | 6.53 | 44 | 57 | 2900 | 7.5 | 3.8 |

| 51 | GD50-200(I)B | 21.8 | 6.06 | 38 | 55 | 2900 | 5.5 | 3.8 |

| 52 | GD50-250(I) | 25 | 6.94 | 80 | 50 | 2900 | 15 | 3.8 |

| 53 | GD50-250(I)A | 23.4 | 6.5 | 70 | 50 | 2900 | 11 | 3.8 |

| 54 | GD50-250(I)B | 21.6 | 6 | 60 | 48 | 2900 | 11 | 3.8 |

| 55 | GD50-315(I) | 25 | 6.94 | 125 | 40 | 2900 | 30 | 3.8 |

| 56 | GD50-315(I)A | 23.7 | 6.58 | 113 | 40 | 2900 | 22 | 3.8 |

| 57 | GD50-315(I)B | 22.5 | 6.25 | 101 | 39 | 2900 | 18.5 | 3.8 |

| 58 | GD50-315(I)C | 20.6 | 5.72 | 85 | 38 | 2900 | 15 | 3.8 |

| 59 | GD65-100 | 25 | 6.94 | 12.5 | 69 | 1450 | 1.2 | 3.8 |

| 60 | GD65-100A | 22.3 | 6.19 | 10 | 67 | 1450 | 1.1 | 3.8 |

| 61 | GD65-125 | 25 | 6.94 | 20 | 68 | 1450 | 3 | 3.8 |

| 62 | GD65-125A | 22.3 | 6.19 | 16 | 66 | 1450 | 2.2 | 3.8 |

| 63 | GD65-160 | 25 | 6.94 | 32 | 63 | 1450 | 4 | 3.8 |

| 64 | GD65-160A | 23.4 | 6.5 | 28 | 62 | 1450 | 4 | 3.8 |

| 65 | GD65-160B | 21.6 | 6 | 24 | 58 | 1450 | 3 | 3.8 |

| 66 | GD65-200 | 25 | 6.94 | 50 | 58 | 2900 | 7.5 | 3.8 |

| 67 | GD65-200A | 23.5 | 6.53 | 44 | 57 | 2900 | 7.5 | 3.8 |

| 68 | GD65-200B | 21.8 | 6.06 | 38 | 55 | 2900 | 5.5 | 3.8 |

| 69 | GD65-250 | 25 | 6.94 | 80 | 50 | 2900 | 15 | 3.8 |

| 70 | GD65-250A | 23.4 | 6.5 | 70 | 50 | 2900 | 11 | 3.8 |

| 71 | GD65-250B | 21.6 | 6 | 60 | 49 | 2900 | 11 | 3.8 |

| 72 | GD65-315 | 25 | 6.94 | 125 | 40 | 2900 | 30 | 3.8 |

| 73 | GD65-315A | 23.7 | 6.58 | 113 | 40 | 2900 | 22 | 3.8 |

| 74 | GD65-315B | 22.5 | 6.25 | 101 | 39 | 2900 | 18.5 | 3.8 |

| 75 | GD65-315C | 20.6 | 5.72 | 85 | 38 | 2900 | 15.5 | 3.8 |

| 76 | GD65-100(I) | 50 | 13.9 | 12.5 | 73 | 1450 | 3 | 4.2 |

| 77 | GD65-100(I)A | 44.7 | 12.5 | 10 | 72 | 1450 | 2.2 | 4.2 |

| 78 | GD65-125(I) | 50 | 13.9 | 20 | 72.5 | 1450 | 5.5 | 4.2 |

| 79 | GD65-125(I)A | 45 | 12.5 | 16 | 71 | 1450 | 4 | 4.2 |

| 80 | GD65-160(I) | 50 | 13.9 | 32 | 71 | 1450 | 7.5 | 4.2 |

| 81 | GD65-160(I)A | 46.7 | 13 | 28 | 70 | 1450 | 7.5 | 4.2 |

| 82 | GD65-160(I)B | 43.3 | 12 | 24 | 69 | 1450 | 5.5 | 4.2 |

| 83 | GD65-200(I) | 50 | 13.9 | 50 | 67 | 2900 | 15 | 4.2 |

| 84 | GD65-200(I)A | 47 | 13.1 | 44 | 66 | 2900 | 11 | 4.2 |

| 85 | GD65-200(I)B | 43.5 | 12.1 | 38 | 65 | 2900 | 7.5 | 4.2 |

| 86 | GD65-250(I) | 50 | 13.9 | 80 | 59 | 2900 | 22 | 4.2 |

| 87 | GD65-250(I)A | 46.7 | 13 | 70 | 59 | 2900 | 18.5 | 4.2 |

| 88 | GD65-250(I)B | 43.3 | 12 | 60 | 58 | 2900 | 15 | 4.2 |

| 89 | GD65-315(I) | 50 | 13.9 | 125 | 54 | 2900 | 34 | 4.2 |

| 90 | GD65-315(I)A | 46.5 | 12.9 | 110 | 54 | 2900 | 30 | 4.2 |

| 91 | GD65-315(I)B | 44.5 | 12.4 | 100 | 53 | 2900 | 30 | 4.2 |

| 92 | GD65-315(I)C | 41 | 11.4 | 85 | 51 | 2900 | 22 | 4.2 |

| 93 | GD80-100 | 50 | 13.9 | 12.5 | 73 | 1450 | 3 | 4.2 |

| 94 | GD80-100A | 44.7 | 12.4 | 10 | 72 | 1450 | 2.2 | 4.2 |

| 95 | GD80-125 | 50 | 13.9 | 20 | 72.5 | 1450 | 5.5 | 4.2 |

| 96 | GD80-125A | 45 | 12.5 | 16 | 71 | 1450 | 4 | 4.2 |

| 97 | GD80-160 | 50 | 13.9 | 32 | 71 | 1450 | 7.5 | 4.2 |

| 98 | GD80-160A | 46.7 | 13 | 28 | 70 | 1450 | 7.5 | 4.2 |

| 99 | GD80-160B | 43.3 | 12 | 24 | 69 | 1450 | 5.5 | 4.2 |

| 100 | GD80-200 | 50 | 13.9 | 50 | 67 | 2900 | 15.5 | 4.2 |

| 101 | GD80-200A | 47 | 13.1 | 44 | 66 | 2900 | 11 | 4.2 |

| 102 | GD80-200B | 43.5 | 12.1 | 38 | 65 | 2900 | 7.5 | 4.2 |

| 103 | GD80-250 | 50 | 13.9 | 80 | 59 | 2900 | 22 | 4.2 |

| 104 | GD80-250A | 46.7 | 13 | 70 | 59 | 2900 | 18.5 | 4.2 |

| 105 | GD80-250B | 43.3 | 12 | 60 | 58 | 2900 | 15 | 4.2 |

| 106 | GD80-315 | 50 | 13.9 | 125 | 54 | 2900 | 37 | 4.2 |

| 107 | GD80-315A | 46.5 | 12.9 | 110 | 54 | 2900 | 30 | 4.2 |

| 108 | GD80-315B | 44.5 | 12.4 | 100 | 53 | 2900 | 30 | 4.2 |

| 109 | GD80-315C | 41 | 11.4 | 85 | 51 | 2900 | 22 | 4.2 |

| 110 | GD80-100(I) | 100 | 27.8 | 12.5 | 76 | 1450 | 5.5 | 4.2 |

| 111 | GD80-100(I)A | 89 | 24.7 | 10 | 74 | 1450 | 4 | 4.2 |

| 112 | GD80-125(I) | 100 | 27.8 | 20 | 76 | 1450 | 11 | 4.2 |

| 113 | GD80-125(I)A | 89 | 24.7 | 16 | 74 | 1450 | 7.5 | 4.2 |

| 114 | GD80-160(I) | 100 | 27.8 | 32 | 76 | 1450 | 15 | 4.2 |

| 115 | GD80-160(I)A | 93.5 | 26 | 28 | 74 | 1450 | 11 | 4.2 |

| 116 | GD80-160(I)B | 86.6 | 24.1 | 24 | 72 | 1450 | 11 | 4.2 |

| 117 | GD80-200(I) | 100 | 27.8 | 50 | 74 | 1450 | 22 | 4.2 |

| 118 | GD80-200(I)A | 93.5 | 26 | 44 | 73 | 1450 | 18.5 | 5.5 |

| 119 | GD80-200(I)B | 87 | 24.2 | 38 | 71 | 1450 | 15 | 5.5 |

| 120 | GD100-100 | 100 | 27.8 | 12.5 | 76 | 1450 | 5.5 | 5.5 |

| 121 | GD100-100A | 89 | 24.7 | 10 | 74 | 1450 | 4 | 5.5 |

| 122 | GD100-125 | 100 | 27.8 | 20 | 76 | 1450 | 11 | 5.5 |

| 123 | GD100-125A | 89 | 24.7 | 16 | 74 | 1450 | 7.5 | 5.5 |

| 124 | GD100-160 | 100 | 27.8 | 32 | 76 | 1450 | 15 | 5.5 |

| 125 | GD100-160A | 93.5 | 26 | 28 | 74 | 1450 | 11 | 5.5 |

| 126 | GD100-160B | 86.6 | 24.1 | 24 | 72 | 1450 | 11 | 5.5 |

| 127 | GD100-200 | 100 | 27.8 | 50 | 74 | 1450 | 22 | 5.5 |

| 128 | GD100-200A | 93.5 | 26 | 44 | 73 | 1450 | 18.5 | 5.5 |

| 129 | GD100-200B | 87 | 27.2 | 38 | 71 | 1450 | 15 | 5.5 |

| 130 | GD125-100 | 160 | 44.4 | 12.5 | 82 | 1450 | 11 | 5.5 |

| 131 | GD125-100A | 143 | 39.7 | 10 | 77 | 1450 | 7.5 | 5.5 |

| 132 | GD125-125 | 160 | 44.4 | 20 | 80 | 1450 | 15 | 5.5 |

| 133 | GD125-25A | 143 | 39.7 | 16 | 77 | 1450 | 11 | 5.5 |

| 134 | GD125-160 | 160 | 44.4 | 32 | 78 | 1450 | 22 | 5.5 |

| 135 | GD125-160A | 150 | 41.7 | 28 | 76 | 1450 | 18.5 | 5.5 |

| 136 | GD125-1160B | 138 | 38.3 | 24 | 73 | 1450 | 15 | 5.5 |

| 137 | GD125-200 | 160 | 44.4 | 50 | 77 | 1450 | 37 | 5.5 |

| 138 | GD125-200A | 150 | 41.7 | 44 | 76 | 1450 | 30 | 5.5 |

| 139 | GD125-200B | 138 | 38.3 | 37.5 | 75 | 1450 | 22 | 5.5 |

| 140 | GD150-200 | 200 | 55.6 | 12.5 | 78 | 1450 | 15 | 5 |

| 141 | GD150-200A | 179 | 49.7 | 10 | 76 | 1450 | 11 | 5 |

| 142 | GD150-250 | 200 | 55.6 | 20 | 79 | 1450 | 18.5 | 5 |

| 143 | GD150-250A | 184.4 | 51.2 | 17 | 78 | 1450 | 15 | 5 |

| 144 | GD150-250B | 167 | 46.4 | 14 | 76 | 1450 | 11 | 5 |

| 145 | GD150-315 | 200 | 55.6 | 32 | 78 | 1450 | 30 | 5.5 |

| 146 | GD150-315A | 187 | 51.9 | 28 | 77 | 1450 | 22 | 5.5 |

| 147 | GD150-315B | 173 | 48.1 | 24 | 76 | 1450 | 18.5 | 5.5 |

| 148 | GD150-400 | 200 | 55.6 | 50 | 75 | 1450 | 45 | 5.5 |

| 149 | GD150-400A | 187 | 51.9 | 44 | 74 | 1450 | 37 | 5.5 |

| 150 | GD150-400B | 174 | 48.3 | 38 | 73 | 1450 | 30 | 5.5 |

| 151 | GD150-400C | 160 | 44.4 | 32 | 71 | 1450 | 22 | 5.5 |

| 152 | GD200-200 | 200 | 55.6 | 12.5 | 78 | 1450 | 15 | 5 |

| 153 | GD200-200A | 179 | 49.7 | 10 | 76 | 1450 | 11 | 5 |

| 154 | GD200-250 | 200 | 55.9 | 20 | 79 | 1450 | 18.5 | 5 |

| 155 | GD200-250A | 184.4 | 51.2 | 17 | 78 | 1450 | 15 | 5 |

| 156 | GD200-250B | 167 | 46.4 | 14 | 76 | 1450 | 11.1 | 5 |

| 157 | GD200-315 | 200 | 55.6 | 32 | 78 | 1450 | 30 | 5.5 |

| 158 | GD200-315A | 187 | 51.9 | 28 | 77 | 1450 | 22 | 5.5 |

| 159 | GD200-315B | 173 | 48.1 | 24 | 76 | 1450 | 18.5 | 5.5 |

| 160 | GD200-400 | 200 | 55.6 | 50 | 75 | 1450 | 45 | 5.5 |

| 161 | GD200-400A | 187 | 51.9 | 44 | 74 | 1450 | 37 | 5.5 |

| 162 | GD200-400B | 174 | 48.3 | 38 | 73 | 1450 | 30 | 5.5 |

| 163 | GD200-400C | 160 | 44.4 | 32 | 71 | 1450 | 22 | 5.5 |

| 164 | GD200-200(I) | 400 | 111.1 | 12.5 | 80 | 1450 | 22 | 5.5 |

| 165 | GD200-200(I)A | 358 | 99.4 | 10 | 78 | 1450 | 18.5 | 5.5 |

| 166 | GD200-250(I) | 400 | 111.4 | 20 | 80 | 1450 | 30 | 5.5 |

| 167 | GD200-250(I)A | 358 | 99.4 | 16 | 78 | 1450 | 22 | 5.5 |

| 168 | GD200-250(I)B | 322 | 89.4 | 13 | 75 | 1450 | 18.5 | 5.5 |

| 169 | GD200-315(I) | 400 | 111.4 | 32 | 80 | 1450 | 55 | 5.5 |

| 170 | GD200-315(I)A | 374 | 103.9 | 28 | 79 | 1450 | 45 | 5.5 |

| 171 | GD200-315(I)B | 346 | 96.1 | 24 | 78 | 1450 | 37 | 5.5 |

| 172 | GD200-400(I) | 400 | 111.4 | 50 | 81 | 1450 | 75 | 5.5 |

| 173 | GD200-400(I)A | 374 | 103.9 | 44 | 80 | 1450 | 75 | 5.5 |

| 174 | GD200-400(I)B | 346 | 96.1 | 30 | 78 | 1450 | 55 | 5.5 |

| 175 | GD200-400(I)C | 320 | 88.9 | 32 | 76 | 1450 | 45 | 5.5 |

| 176 | GD300-235 | 720 | 200 | 18 | 81 | 970 | 55 | 6 |

| 177 | GD300-235A | 657 | 182.5 | 15 | 79 | 970 | 45 | 6 |

| 178 | GD300-235B | 600 | 167 | 12.5 | 77 | 970 | 37 | 6 |

| 179 | GD300-300 | 720 | 200 | 28 | 81 | 970 | 75 | 6 |

| 180 | GD300-300A | 666 | 185 | 24 | 80 | 970 | 75 | 6 |

| 181 | GD300-300B | 623 | 173.1 | 21 | 79 | 970 | 55 | 6 |

| 182 | GD300-380 | 720 | 200 | 44 | 84 | 970 | 132 | 6 |

| 183 | GD300-380A | 666 | 185 | 38 | 80 | 970 | 110 | 6 |

| 184 | GD300-380B | 614 | 170.6 | 32 | 78 | 970 | 90 | 6 |

| 185 | GD300-235(I) | 1080 | 300 | 40 | 82 | 970 | 160 | 6 |

| 186 | GD300-235(I)A | 965 | 268.1 | 32 | 80 | 970 | 132 | 6 |

进口管道离心泵一般输送介质温度可达350℃,流量可达300m3/h,扬程可达115m,适用于热介质油和热水等高温液体。

1、定时记录电源电压的变化和电压的不平衡度。电源电压过高或过低,三相电压的不平衡造成电流的不平衡,都可能引起电机的过热或其它不正常现象。

2、定时记录电泵的负载电流和不平衡度。电泵发生故障时大多数会反映到定子绕组的电流的剧增,使电机过热。

3、定时记录管路中的输液温度,以确保实际的输液温度低于或等于铭牌上所规定的输液温度,避免电泵长期处于超温状态下运行,降低电机的使用寿命。

4、定时记录电泵进、出口端上的压力表数值,进口处力表的数值不得小于零,出口处压力表数与进口处压力表数的差值,必须符合牌上的规定的压力值。

5、电泵在每一次使用前要排气一次,在长期运行时,必须每星期排一次气,因为泵长时间运行,水分子在电泵内高速搅拌和撞击,同时被输送的介质带有一定的温度,造成液体浆产生。

6、注意电泵的气味,振动和噪声,电机的绕组因温度过高就会发出绝缘的焦味。一般的机械故障会反映为振动和噪声。因此发现异常应立即停电检查。

7、定时检查电泵循环液通路,过滤装置是否有阻塞现象。

8、定期维修测量石墨轴承和轴套之间的间隙,以确保定子屏蔽套与转子屏蔽套之间间隙均匀,运转可靠。

9、定期检查叶轮口环与泵体的配合间隙,因此间隙会直接影响电泵的性能,在一般情况下,间隙超过1.5mm,则应更换新的叶轮,在特殊情况下也可采用修补工艺来改善。

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostruds exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered

There are many variations of passagai of Lorem Ipsum available but the ma jority have suffered